Before we talk about plastic injection mold making process,Let’s explain what plastic injection mold is first:

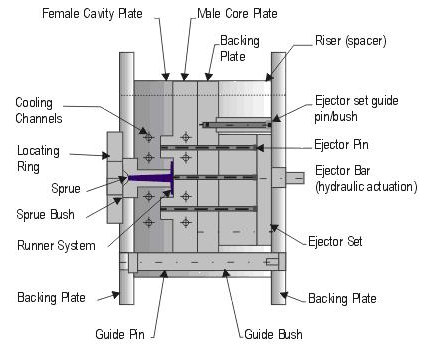

Designed as a hollow metal block with cavities, a plastic injection mold is used to give shape to molten plastics via the process of injection. Though you may not see them shown in the following figure, in fact, there are multiple holes made inside the mold to realize temperature control by way of oil, water or heaters.

A sprue in the mold allows the melted plastic to flow in, which will then fill the cavities through the runners and gates. After being cooled, the mold will be opened, and the molded parts will be further ejected by a push on the ejector plate by the ejector rod of the injection molding machine

- Guide Pins– Installed to one half of the plastic injection mold and align the two halves by entering the holes in the other half. the most function is to locate the core and cavity insert in right position, avoid steps on parting line of molding parts or mismatch between two halves of molds.

- Runner– Connect the sprue bush to molding cavities, it is a passageway of flow material, the section shape is usually round or trapezoid.

- Gate–The narrowest position of the runner, where the flow material enters the molding cavity. There are many different types, some will be broken from molding part when ejecting out. such as submarine gate, tunnel gate. Some need to be cut after molding. like tab gate, side gate and so on.

- Sprue (Bush) – Tapered hole in the center of the plastic injection mold into which the flow material travel from the nozzle of injection machine to runners

- Locating Ring– Locating the plastic injection mold on the fixed platen of injection machines, so that the injection nozzle lines up with the sprue bush.

- Mould Cavity(include cavity and core)– The space in the mold shaped to produce molding product.

- The ejector (Pins)– Push the runner and molding parts out of the mold

- The Shot– Total amount of material into cavities, include runner and molding parts

- Ejector plate/Ejector backplate: Just for hold the ejectors in the right position

- Clamping plate: Clamping the mold to the platen of injection machines